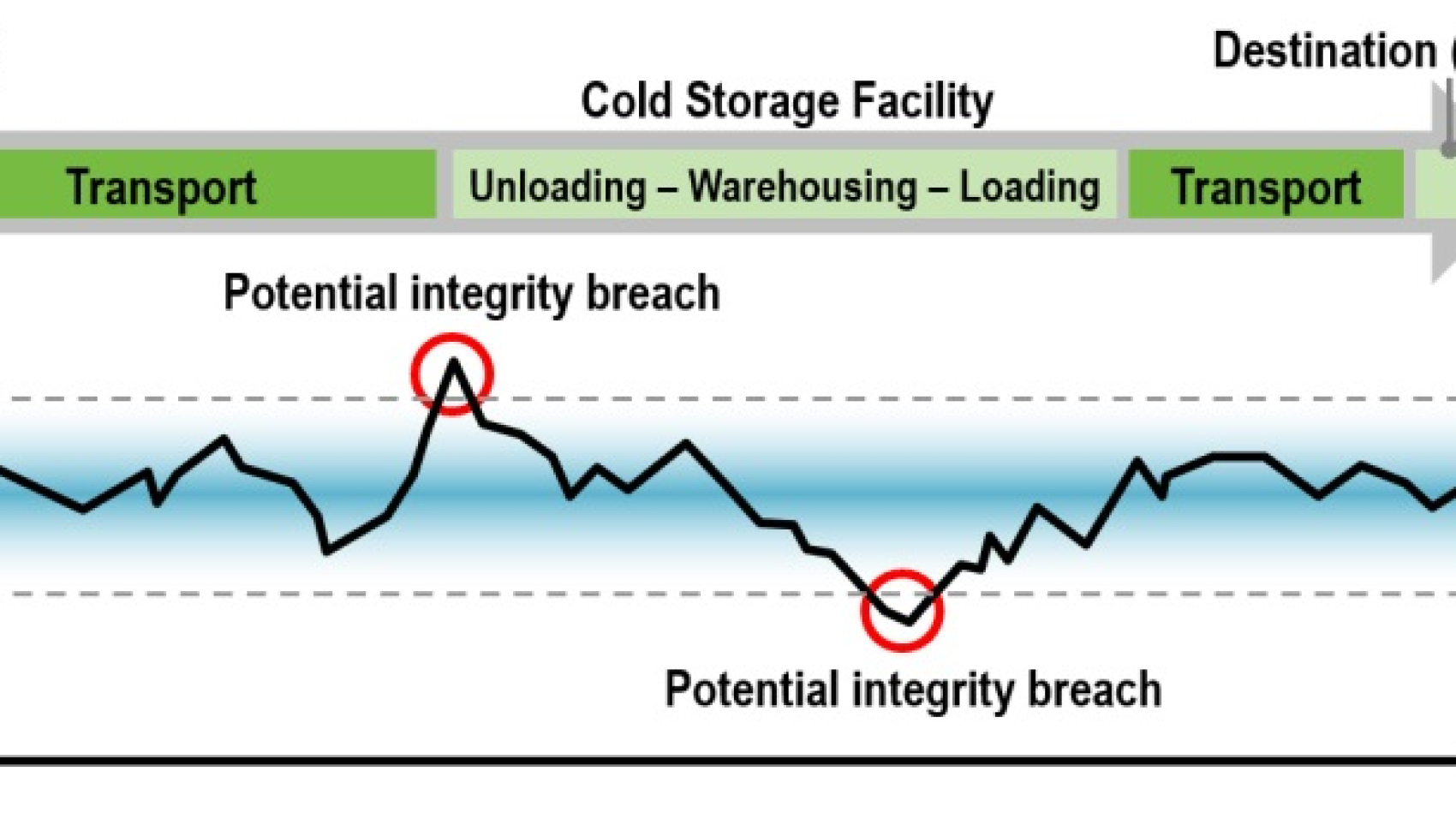

Cold Supply Chain organizations continue to lose millions because of spoilage from temperature fluctuations and potential hazards for consumers and subsequent regulatory actions.

The organizations produce the majority of biologics products, which are highly sensitive to storage conditions. Temperature monitoring must be done by following cold chain processes, whether they are in storage or in transit.

Biological products have a large proportion of shorter shelf lives and carry strict temperature requirements.

Understanding IoT

The IoT signifies smart devices connected through sensors and the Internet that performs tasks and exchange real-time data. The IoT application, such as cold chain monitoring, resources (man and machine) tracking, packaging, and warehouse management, is very much suited to cold supply chain management.

The IoT can help manage supply chains, improve services, and products, so industries have a compelling opportunity to adopt and profit from the IoT, the game-changing technology.

The rapid expansion of IoT devices provides enough potential to organizations by harnessing and using data collected through smart devices in the supply chain lifecycle]. IoT is defined as a network of uniquely identifiable endpoints or things that communicate without human interaction using IP. connectivity, whether locally or globally.

The IoT is also defined as the extended development of internet services to consider smart objects that exist. Supply chain integration is critical for improving business performances and can be achieved through cost reduction, improving responsiveness, increasing service level, and streamlining organizations’ decision-making processes.

The IoT has a significant role in the warehousing and distribution cycle of the supply chain. Smart objects are connected to the Internet using their communication protocol and are continuously collecting and processing the data. The role of IoT mostly starts from manufacturing for shop floor visibility and then moves to the warehouse for real-time inventory visibility, and then finally during distribution toward higher fleet management for real-time cold chain processes.

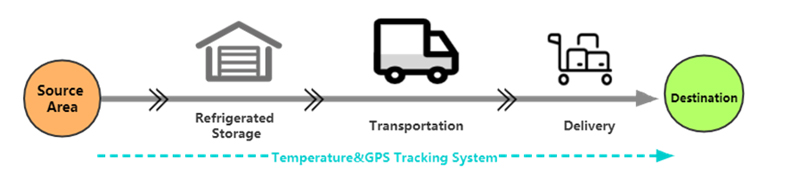

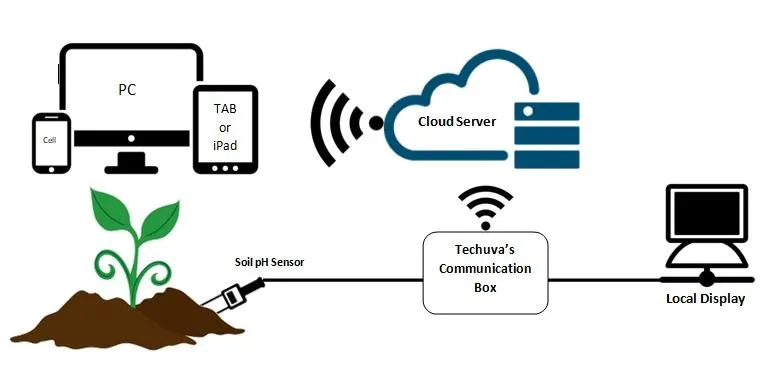

IoT solutions can help cold chain organizations remotely monitor cold chain environments in real-time by embedding sensors on tracking equipment using smartphones and tablets. IoT models can provide information, such as (a) product carrier information, (b) continuous monitoring using sensors, (c) location tracking using GPS, and (d) regular and urgent notifications containing carrier temperatures, humidity, and location information with a timestamp.

A smart manufacturing factory’s communication system comprises a wireless sensor network for connecting the sensor module and gateway, and then the sensor and sensor module is distributed to the necessary position in the factory. Smart equipment using IoT solutions collects operational data and status, allows visibility across equipment, and real-time dynamic scheduling of shop floor activities.

The solution helps in reducing equipment downtime, and the utilization rate improves. Sensors can also help collect metadata to identify and reduce process variability and improve production yield to enhance productivity, efficiencies, and cycle time.

The warehouse is an important area for the cold chain industry. The business managers manage many storage facilities globally to ensure a continuous and timely supply of their products in a cost-efficient manner. Real-time visibility and three-dimensional view of warehouse operations allow warehouse managers (a) monitor and track the storage of sensitive products in controlled zones, (b) track inventory of finished goods, and (c) identify problem areas and assign resources to deal with issues requiring human interventions.

Conclusion

IoT is an enabler to spur growth within cold supply chain organizations. These organizations are more reactive than proactive in technology adoption, such as IoT despite a positive influence on the supply chain system. Underlying issues such as privacy, reliability, authentication, access control, and security issues need to be addressed before unleashing IoT applications’ unlimited potential and utility in these industries.

Increasing customer expectations towards perishable products’ potency and non-compliance with regulatory agencies have put pressure on management. These companies now started implementing IoT to enable value chain end-to-end integration.

Big data analytics and cognitive systems, such as artificial intelligence and machine learning help cold chain organizations by getting inputs from IoT devices and in the process improved the productivity of the cold chain process and the entire supply chain ecosystem. Technology is evolving every day in all industries including pharmaceuticals.

Check out our end-to-end cold supply chain temperature and humidity monitoring solution